XENON VERTICAL HORIZONTAL PUMPS are used to draw liquid from a deep tank or well. They come in a variety of shapes, sizes, and functions, but all have a distinctive vertical configuration that moves liquids in the vertical direction upward through a pipe. They can be used in a range of operating temperatures from low to high, with varying pressures, and with many liquids ranging from ordinary water services to corrosive, flammable, and even difficult to process liquids and chemicals.

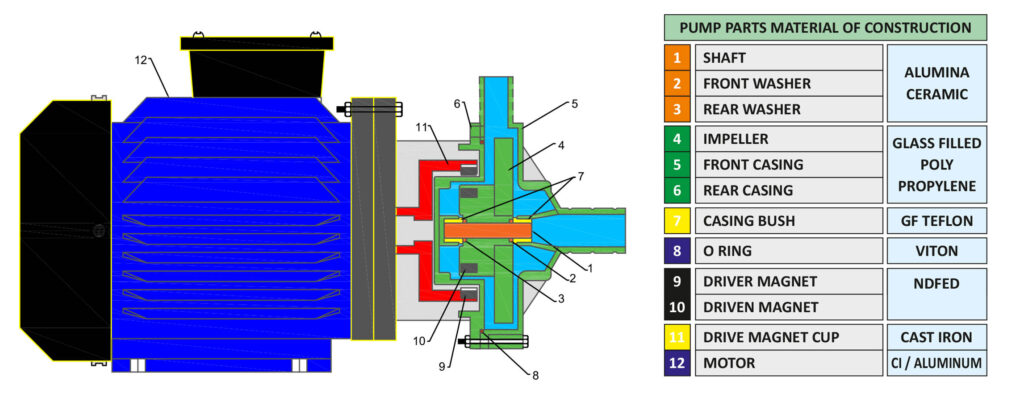

A centrifugal pump is designed for handling the corrosive fluids involved in waste treatment, sump draining, tank transfer, agitation, wet process, and other industrial applications. It transports fluids by the conversion of rotational kinetic energy to the hydrodynamic energy of the fluid flow. This type of rotational energy typically comes from an engine or electric motor. Fluids enter the rapidly rotating impeller along its axis and are cast out through centrifugal force along its circumference through the impeller’s vane tips. This action by the impeller increases the fluid’s velocity and pressure and also directs it toward the pump outlet. The pump casing is designed to constrict fluid from the pump inlet, direct it into the impeller, then slow and control the fluid before discharge.

| Casing Impeller | Casing: Cast iron, Bronze, Nodular Cast Iron, Stainless Steel Impeller |

| Max. capacity | 1500 m3/h (6600 GPM) |

| Max. delivery head | 160 m (525 ft |

| Max. liquid temp | 200°C (392°F |

| Max. pressure | 1000 kPa (25 bar) |

| Max. speed/td> | 3 600 rpm |

| M.O.C. | Ductile Iron, CF8M (316) SS, CD4MCuN and Alloy 20 materials available |

Absolutely fantastic!

My business was struggling

and now I have more work

than I can handle!

Mike Jones – Wigan

Three years ago, I had one van and struggling to get work, and now I have seven vans and a team of 16 roofers!

Jason Williams – Wirral

Whatever you guys are doing, keep doing it! My workload has skyrocketed and I'm booked up for months!

Peter Henderson - London

The best money I have ever spent trying to grow my business! There's so many scammers out there!

Adam Waters - Birmingham

© 2025 Copyright: Xenon Engineerings.com

© 2025 Water Pump Manufacturing. All rights reserved. | Designed with ❤️