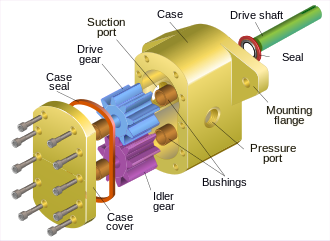

Xenon Gear Pumps are a type of Rotary Positive Displacement Pump. They consist of at least two separate and rotating gears with intermeshing teeth. As these meshed teeth separate, they create a partial vacuum which is filled by the fluid being pumped. As the gears then continue to rotate the fluid becomes trapped and is carried around the casing to the discharge side of the pump.

Here as the gear teeth begin to re-mesh the fluid is ejected creating a pumping action. There are a number of different Gear Pump designs but ultimately they all employ this same pumping principle. Note that contrary to common belief, pumps do not suck! Instead they create a partial vacuum within them which becomes filled or partially filled by the fluid which must be at a higher pressure for it to work.

The initial fluid pressure might be atmospheric or it maybe be greater or less than atmospheric depending upon the system. In effect the fluid is pushed into the pump as a result of this pressure difference between the outside and the inside of the pump.

External precision gear pumps are usually limited to maximum working pressures of around 210 bars (21,000 kPa) and maximum rotation speeds around 3,000 RPM. Some manufacturers produce gear pumps with higher working pressures and speeds but these types of pumps tend to be noisy and special precautions may have to be made.[3]

Suction and pressure ports need to interface where the gears mesh (shown as dim gray lines in the internal pump images). Some internal gear pumps have an additional, crescent-shaped seal (shown above, right). This crescent functions to keep the gears separated and also reduces eddy currents.

Pump formulas:

Gear pumps are generally very efficient, especially in high-pressure applications.

Factors affecting efficiency:

| Capacity | Typically up to 500 m³/hr (depending on size and design) |

| Discharge Pressure | Can handle up to 200 bar (common range: 10–100 bar for standard industrial gear pumps) |

| Viscosity Range | Typical range: 1 to 1,000,000 cSt depending on design |

| Temperature | Standard: –20°C to +200°C |

| Speed | Typically 50 to 1750 rpm (depending on motor and application) |

| Suction Conditions | Net Positive Suction Head Required (NPSHR): generally <2 m for low-viscosity fluids |

| M.O.C. | Stainless Steel (SS 304/316) |

Absolutely fantastic!

My business was struggling

and now I have more work

than I can handle!

Mike Jones – Wigan

Three years ago, I had one van and struggling to get work, and now I have seven vans and a team of 16 roofers!

Jason Williams – Wirral

Whatever you guys are doing, keep doing it! My workload has skyrocketed and I'm booked up for months!

Peter Henderson - London

The best money I have ever spent trying to grow my business! There's so many scammers out there!

Adam Waters - Birmingham

© 2025 Copyright: Xenon Engineerings.com

© 2025 Water Pump Manufacturing. All rights reserved. | Designed with ❤️