POLYPROPYLENE MONOBLOCK PUMPS (Series CNR)

- Home

- POLYPROPYLENE MONOBLOCK PUMPS (Series CNR)

POLYPROPYLENE MONOBLOCK PUMPS (Series CNR)

Feature

- Single stage horizontal Centrifugal Pump.

- Pumps Designed according to DIN 34256 & ISO 2858

- Hight Level Of Durability and Reliability

- Quick disassemble and reassemble

- Cost effective with low running and maintenance costs.

- Compact in design for less space occupation.

- Heavy Duty one piece casting of SS316 parts with streamlined volute design gives high efficiency with outstanding performance and power savings.

Specifications

| Flow Upto | Max 50m3 / hr |

| Head upto | Max 52 Meters |

| Max Motor Power | 7.5 kw or 10 hp |

| Temperature Range | -25 °C to 150 °C |

| Max Working Pressure | 5 kgs |

| Flange Class | ANSI Class 150 |

| Impeller Type | Semi Open |

| MOC | SS 316 |

| Mechanical Seal | Sic, TC with PTFE Elastomers |

Industries We Server

- Acid & Chemical Industries

- Pharmaceutical Industries

- Food & Beverage Industries

- Paper & Pulp Industries

- Agrochemical Industries

| Model | Size | HP | PERFORMANCE DATA: HEAD (METERS) / FLOW (LPM) | ||||||||||||||

| HEAD | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 22 | 24 | 26 | 28 | 32 | 35 | 40 | ||

| CNR 2 | 1” X 1” | 0.5 | 122 | 102 | 84 | 66 | 48 | ||||||||||

| CNR 2A | 1.5“ X 1.5” | 0.5 | 200 | 152 | 60 | 22 | |||||||||||

| CNR 3 | 1” X 1” | 1 | 160 | 140 | 128 | 120 | 98 | 90 | 70 | 40 | |||||||

| CNR 3A | 1” X 1” | 1 | 248 | 225 | 184 | 142 | |||||||||||

| CNR 4A | 1.5” X 1.5” | 1.5 | 186 | 170 | 152 | 143 | 122 | 82 | |||||||||

| CNR 5A | 2 | 2 | 230 | 198 | 180 | 122 | 85 | ||||||||||

| CNR 5B | 2 | 2 | 320 | 290 | 241 | 174 | 115 | ||||||||||

| CNR 6A | 3 | 3 | 230 | 216 | 200 | 191 | 180 | 144 | 73 | 24 | |||||||

| CNR 6B | 3 | 3 | 372 | 341 | 320 | 282 | 266 | 245 | 220 | ||||||||

| HEAD | 16 | 20 | 24 | 28 | 32 | 36 | 40 | 44 | 48 | 52 | 54 | 56 | 58 | 60 | |||

| CNR 7A | 2” x 1.5 | 5 | 260 | 230 | 190 | 140 | 88 | 32 | |||||||||

| CNR 7B | 2.5” X 2” | 5 | 645 | 572 | 518 | 300 | 210 | 145 | |||||||||

| CNR 8A | 2” X 1.5 | 7.5 | 290 | 270 | 250 | 230 | 190 | 126 | 120 | 60 | |||||||

| CNR 8B | 2.5” X 2” | 7.5 | 780 | 700 | 640 | 570 | 470 | 275 | |||||||||

| CNR 9A | 2” X 1.5” | 10 | 500 | 480 | 470 | 450 | 430 | 390 | 340 | 300 | 260 | ||||||

| CNR 9B | 2.5” X 2” | 10 | 700 | 650 | 590 | 492 | 385 | ||||||||||

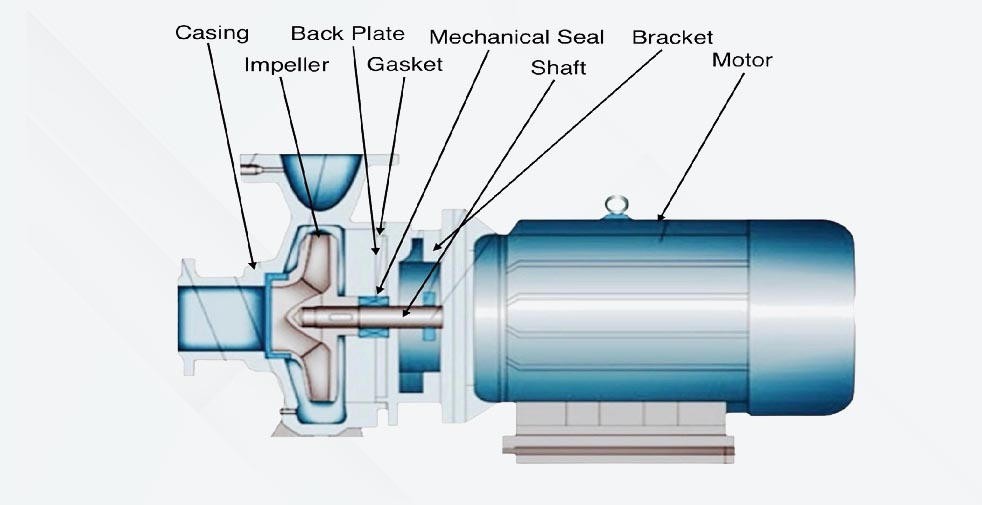

List of Components with MOC

| No. | Description | Material |

| 1 | Casing | SS 316 |

| 2 | Impeller | SS 316 |

| 3 | Back Plate | SS 316 |

| 4 | Gasket | PTFE Teflon |

| 5 | Mechanical Seal | TC, SIC, Carbon with PTFE Elastomers |

| 6 | Shaft | SS 316 |

| 7 | Bracket | Cast Iron |

| 8 | Motor | Cast Iron / Aluminium |