PP Centrifugal pumps (Series PCX)

- Home

- PP Centrifugal pumps (Series PCX)

PP Centrifugal pumps (Series PCX)

PCX Series Horizontal Centrifugal Process Pumps are being designed and manufactured by Taha Group Of companies which are one of the largest manufacturers of industrial Metallic and Non Metallic Chemical Process Pumps. The Company has 15 year of manufacturing experience and the same in brought forward for the benefit of customer to offer most suitable pumps for the most demanding application.

Feature

PCX Series pumps are moulded from virgin raw material and are tested for performance and reliability before deliver to the customer. The volute casing and impeller are designed using the latest CAD Technology to give Optimum Performance and efficiency. All standard pumps are fitted with multistring balanced Teflon bellow type mechanical seal toe ensure zero leakage and give trouble free operation.

Application

PCX series pumps find wide application in over all chemical and other industries.

- Dyes & intermediate industries

- Steel Plants & Re-rolling Plants

- Power Plants – Thermal, Nuclear, Hydel

- Pharmaceuticals & Distilleries

- Alkalis & Caustic Soda Plants

- Electroplating & Pickling Plants

- Pump & Paper Industries

- Cement & refractories plants

Liquids like sulfuric acid, hydrochloric acid, phosphoric acid, Nutric acid, Acetic acid, Caustic Soda, Petroleum Products, Distillery liquids, Pharmaceuticals syrups, Electroplating Chemicals etc all can be handled by choosing different material of construction and seal configuration.

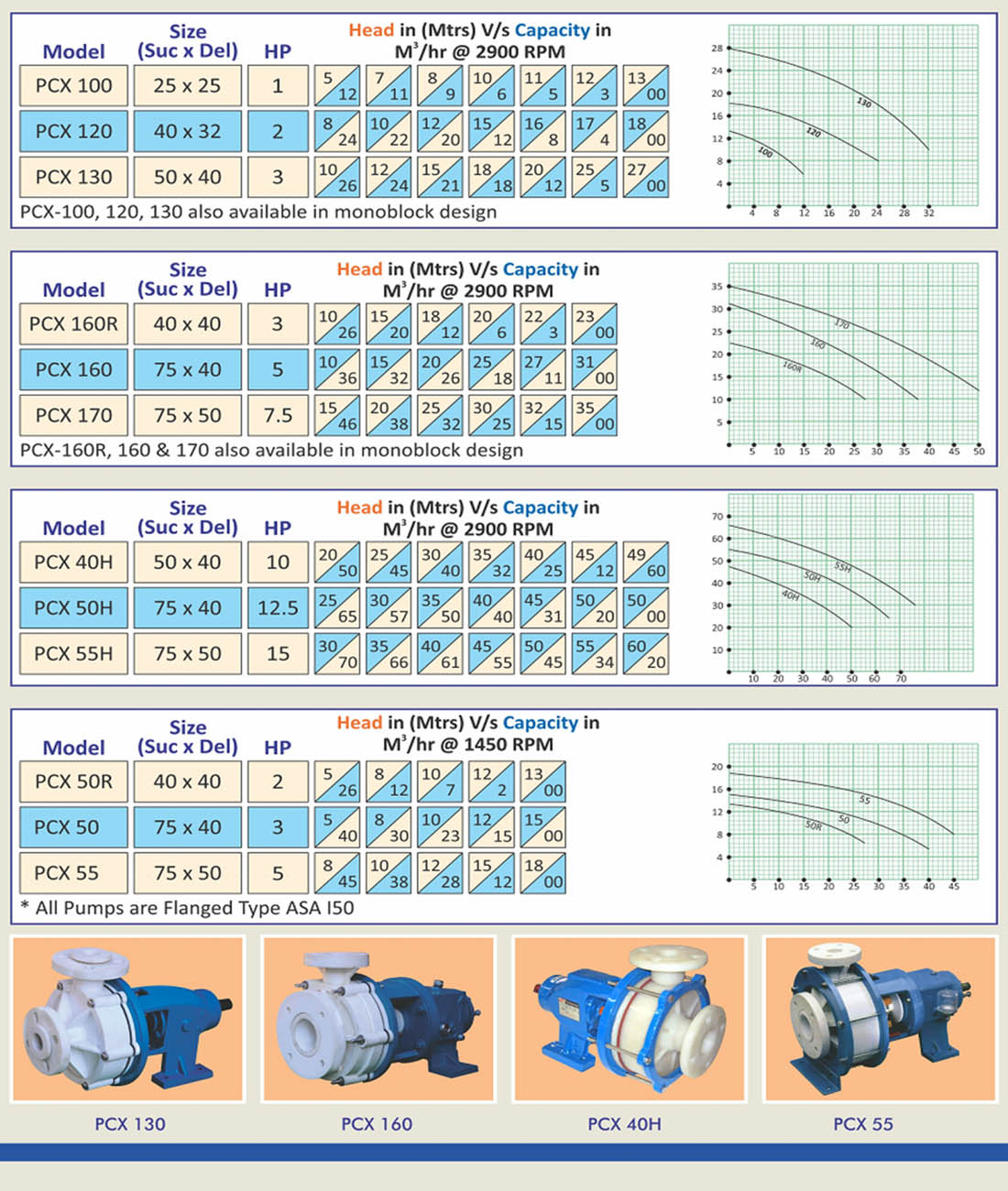

Technical Parameters

Pump Type | Centrifugal Non self priming type |

Max. Operating Temp | 70° C for PP |

| 90° C for PPH |

| 110° C for PVDF |

Sp. Gravity Limit | Upto 1.8 |

Viscosity Limit | Up to 1500 CST |

Particle size Limit | Upto 2 mm |

Material of Construction

| Suction Casing | PP / PPH / PVDF |

| Impeller | PP / PPH / PVDF |

| Back Plate | PP / PPH / PVDF |

| Shaft | EN 8 / SS316 / Hast Alloy |

| Shaft Sleev | High Alumina Ceramic / SS 316 / Hast Alloy |

| Sealing | Teflon Bellow Mech Seal Of GFT v/s Ceramic, Sic v/s Ceramic Or PTFE Gland Packing |

| Bearing Frame | Cast Iron |

| Bearing | Ball Bearing SKF / NACHI / INA |

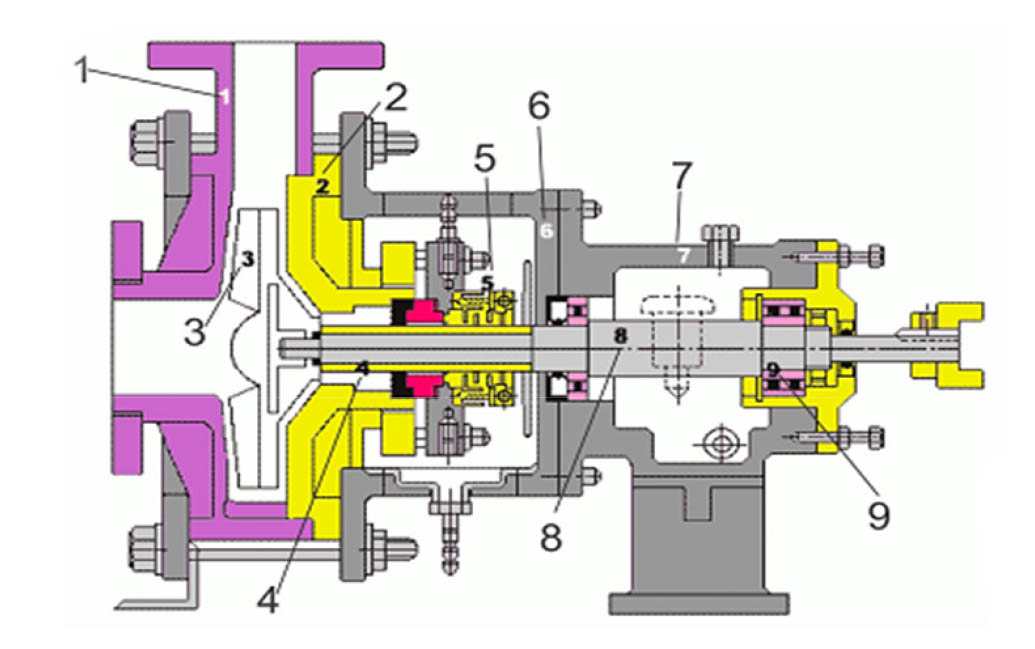

| Sr. | Part Name | Material Of construction |

| 1 | Volute Casing | Polypropylene Co-polymer / PVDF |

| 2 | Backplate | Polypropylene Co-polymer / PVDF |

| 3 | Impeller | Polypropylene Co-polymer / PVDF |

| 4 | Sleeve |

|

|

|

||

| 5 | Sealing |

|

|

|

||

| 6 | Adaptor | Cast Iron |

| 7 | Shaft | EN – 8 or SS-316 |

| 8 | Bearing Frame | Cast Iron |

| 9 | Bearing | Ball Bearing |