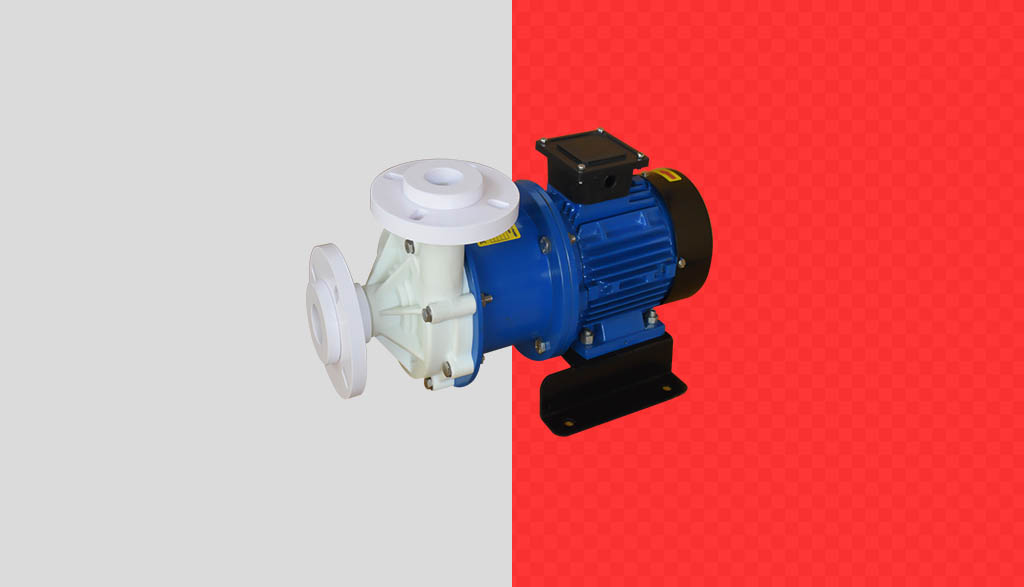

Magnetic drive pumps, also known as mag drive pumps, are a revolutionary type of pump designed to operate without a direct mechanical connection between the motor and the impeller. Instead, they rely on magnetic coupling to transfer motion, eliminating the need for traditional shaft seals. This design makes mag drive pumps highly efficient, leak-proof, and ideal for handling hazardous or corrosive fluids.

Xenon Engineering, a leading manufacturer and supplier of magnetic drive pumps in Surendranagar, New York, United States of America, specializes in providing high-quality mag drive pumps for various industrial applications.

How Do Magnetic Drive Pumps Work?

Magnetic drive pumps function using a magnetic coupling mechanism instead of a conventional shaft-driven system. Here’s a step-by-step breakdown of how they operate:

- Motor Activation: The motor generates rotational energy and transmits it to the outer magnetic assembly.

- Magnetic Coupling: The outer magnet, connected to the motor shaft, transfers rotational energy to the inner magnet, which is attached to the impeller.

- Impeller Rotation: As the inner magnet spins, the impeller rotates, creating fluid movement without direct mechanical contact.

- Fluid Transfer: The pump moves liquid efficiently without requiring shaft seals, preventing leaks and contamination.

This innovative design makes magnetic drive pumps highly reliable and safe for various industrial applications.

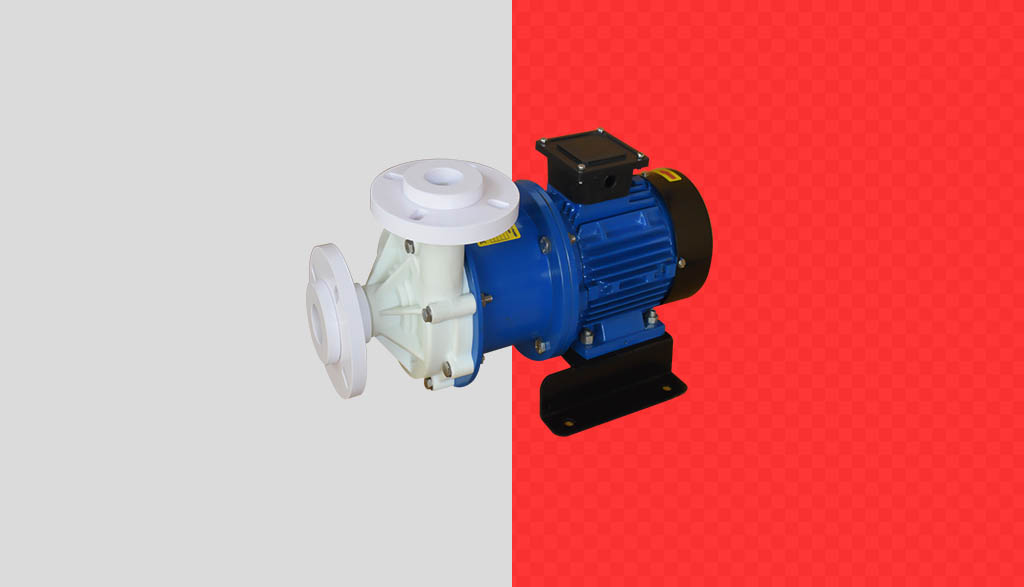

Types of Magnetic Drive Pumps

Magnetic drive pumps are classified based on their design and intended applications. The main types include:

1. Centrifugal Magnetic Drive Pumps

- Most common type.

- Uses centrifugal force to move fluids efficiently.

- Ideal for handling non-viscous and low-viscosity fluids.

2. Positive Displacement Magnetic Drive Pumps

- Designed for high-viscosity and precise dosing applications.

- Includes gear pumps and diaphragm pumps with magnetic coupling.

3. Self-Priming Magnetic Drive Pumps

- Capable of automatically priming without external assistance.

- Used in applications requiring suction lift and air removal.

4. Multistage Magnetic Drive Pumps

- Designed for high-pressure applications.

- Used in boiler feed systems and high-purity chemical processing.

Applications of Magnetic Drive Pumps

Magnetic drive pumps are widely used across multiple industries due to their leak-proof operation and chemical resistance. Some common applications include:

1. Chemical Processing

- Safely handles corrosive and hazardous chemicals.

- Prevents leakage and environmental contamination.

2. Pharmaceutical and Biotechnology

- Ensures contamination-free transfer of sterile fluids.

- Used in laboratory and production environments.

3. Water and Wastewater Treatment

- Pumps chemicals used in water purification.

- Ensures safe handling of aggressive fluids.

4. Food and Beverage Industry

- Transfers food-grade liquids and syrups.

- Eliminates contamination risks with a seal-less design.

5. Oil and Gas Industry

- Handles hydrocarbons, fuels, and lubricants.

- Ensures safe transfer of flammable fluids.

6. Electronics and Semiconductor Manufacturing

- Used for ultra-pure chemical processing.

- Prevents contamination in microchip production.

Advantages of Magnetic Drive Pumps

1. Leak-Proof Design

- No mechanical seals eliminate the risk of fluid leakage.

- Ideal for hazardous and corrosive fluid handling.

2. Low Maintenance

- Fewer moving parts reduce wear and tear.

- Minimizes downtime and maintenance costs.

3. High Efficiency

- Magnetic coupling ensures smooth, energy-efficient operation.

- Reduces energy consumption compared to conventional pumps.

4. Enhanced Safety

- Prevents hazardous fluid leaks, ensuring workplace safety.

- Ideal for explosive and high-risk environments.

5. Corrosion and Chemical Resistance

- Constructed from robust materials like stainless steel and fluoropolymers.

- Handles aggressive chemicals without degradation.

6. Compact and Lightweight

- Space-saving design allows easy installation.

- Suitable for confined spaces and mobile applications.

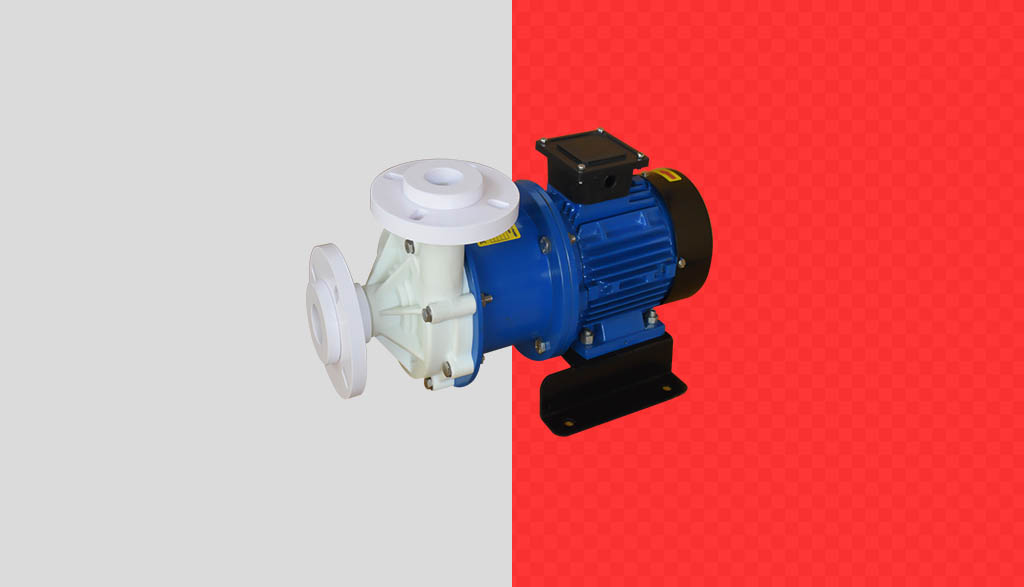

Why Choose Xenon Engineering for Magnetic Drive Pumps?

Xenon Engineering is a trusted manufacturer and supplier of magnetic drive pumps in Surendranagar, New York, United States of America. We offer:

- Premium Quality: High-grade materials ensure durability and efficiency.

- Customization: Tailored solutions for specific industrial needs.

- Competitive Pricing: Affordable solutions without compromising performance.

- Expert Support: Dedicated technical assistance for installation and maintenance.

For reliable magnetic drive pumps, contact Xenon Engineering today and experience top-notch engineering and customer satisfaction.

Magnetic drive pumps provide a leak-proof, energy-efficient, and low-maintenance pumping solution for industries handling hazardous or corrosive fluids. Whether in chemical processing, pharmaceuticals, or wastewater treatment, these pumps ensure safe and reliable operations.

For premium magnetic drive pumps in United States of America, trust Xenon Engineering – your dependable partner for advanced pumping solutions!