+(02) 0111-7457-354

demomax@gmail.com

92 Princess Road, parkvenue

In industrial applications where transferring hazardous or sensitive liquids is crucial, Magnetic Drive Pumps have become the preferred solution. Known for their efficiency and ability to handle corrosive substances, magnetic drive pumps offer a reliable, leak-proof alternative to traditional mechanical seal pumps. At Xenon Engineering, we specialize in the manufacturing of high-quality magnetic drive pumps that cater to a wide range of industries, including chemical processing, pharmaceuticals, water treatment, and more.

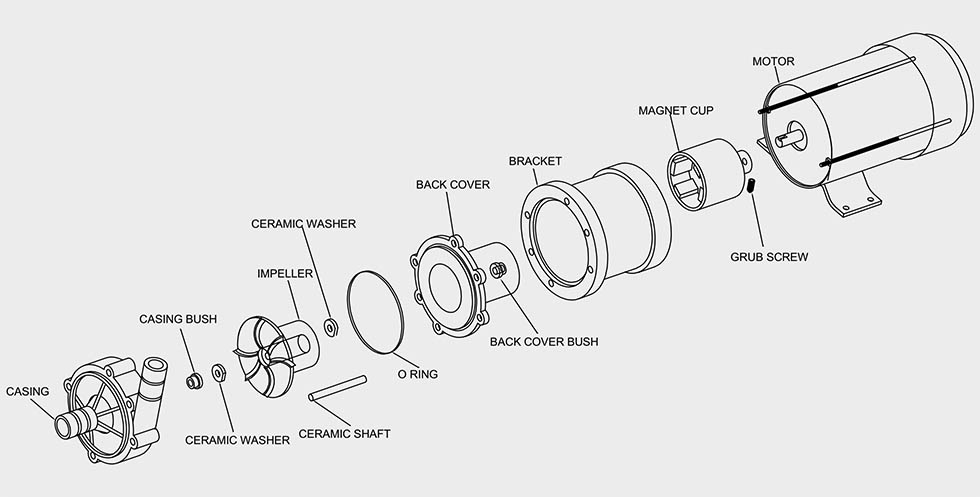

Magnetic drive pumps, or mag drive pumps, operate without the need for a conventional shaft seal. Instead of a mechanical seal, these pumps use a magnetic coupling to transfer the rotational energy from the motor to the impeller. This innovative design makes magnetic drive pumps a highly reliable choice for applications that require the safe handling of volatile, corrosive, or hazardous fluids.

The key feature of magnetic drive pumps is the isolation of the fluid from the environment, ensuring there are no leaks, even with the most demanding liquids. This makes them ideal for industries where fluid containment is critical.

Magnetic drive pumps consist of two key components: an inner magnet attached to the pump impeller and an outer magnet connected to the motor. The two magnets are separated by a containment shell, which creates a completely sealed environment, preventing any fluid from escaping.

When the motor starts, the outer magnet rotates, which in turn causes the inner magnet to rotate. This motion drives the impeller, which moves the fluid through the pump. Since there are no mechanical seals in this design, the risk of leakage is eliminated, offering a safer and more durable solution for fluid transfer.

Leak-Free Operation :

One of the most significant advantages of magnetic drive pumps is their ability to prevent fluid leakage. Since there is no direct connection between the motor and the fluid, and no mechanical seals that can wear down, these pumps provide a sealed, leak-proof system.

Corrosion Resistance

Magnetic drive pumps are typically constructed using materials like PP (Polypropylene), PVDF (Polyvinylidene Fluoride), and SS316 (Stainless Steel), which are known for their corrosion resistance. This makes them suitable for handling corrosive fluids such as acids, solvents, and other aggressive chemicals.

Corrosion Resistance

Magnetic drive pumps are typically constructed using materials like PP (Polypropylene), PVDF (Polyvinylidene Fluoride), and SS316 (Stainless Steel), which are known for their corrosion resistance. This makes them suitable for handling corrosive fluids such as acids, solvents, and other aggressive chemicals.

Lower Maintenance Costs

Traditional pumps with mechanical seals require frequent maintenance due to seal wear and tear. Magnetic drive pumps, with their seal-less design, reduce the need for regular maintenance, saving time and costs in the long run.

Safe for Hazardous Fluids

The fully enclosed design of magnetic drive pumps ensures that no hazardous chemicals or gases escape into the environment, making them ideal for industries that work with dangerous or toxic fluids.

Energy Efficient

Magnetic drive pumps are highly efficient as they reduce frictional losses associated with mechanical seals. Their design also contributes to lower energy consumption, which is an important consideration for large-scale industrial operations.

Magnetic drive pumps are used in a wide range of industries due to their versatility and safety features. Some of the common applications include:

At Xenon Engineering, we pride ourselves on delivering top-quality magnetic drive pumps designed to meet the specific needs of our clients. Our product range includes:

Our pumps are manufactured using advanced materials to ensure high performance, durability, and resistance to corrosive substances. Whether you require a pump for chemical processing or water treatment, Xenon Engineering has the right solution to meet your industrial needs.

Magnetic Drive Pumps Manufacturer in United States of America

Magnetic drive pumps have become an essential tool for industries that require reliable, leak-free, and energy-efficient fluid transfer solutions. With their ability to handle corrosive and hazardous fluids, these pumps offer unmatched safety and performance. Xenon Engineering is committed to providing world-class magnetic drive pumps that meet the stringent demands of industrial operations.

For more information about our product offerings or to discuss your specific requirements, contact Xenon Engineering today and let us help you find the perfect pumping solution for your business.